The energy sector stands at a critical juncture as we approach 2024. With the ongoing global...

The Future of Chip Manufacturing in 2024: Innovations and Challenges

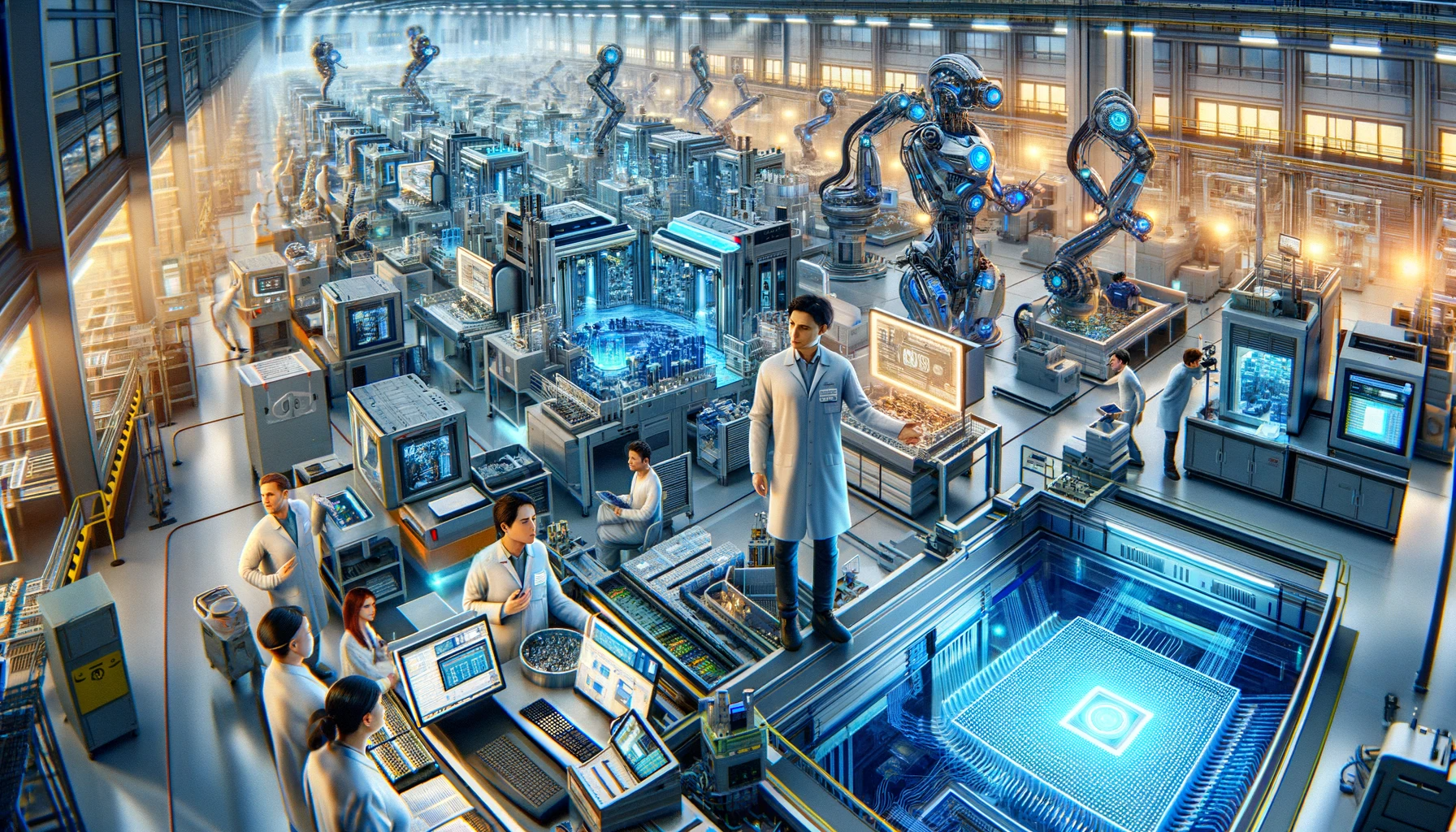

As we venture into 2024, the landscape of chip manufacturing continues to evolve at a pace that's both exhilarating and challenging. This year is poised to witness some significant transformations in the semiconductor industry, driven by advancing technologies, increasing demand, and the global geopolitical climate. In this blog, we'll explore the key trends and innovations shaping the future of chip manufacturing in 2024.

As we venture into 2024, the landscape of chip manufacturing continues to evolve at a pace that's both exhilarating and challenging. This year is poised to witness some significant transformations in the semiconductor industry, driven by advancing technologies, increasing demand, and the global geopolitical climate. In this blog, we'll explore the key trends and innovations shaping the future of chip manufacturing in 2024.

1. Advanced Materials and Nanotechnology

One of the most exciting developments in chip manufacturing is the advent of new materials and the application of nanotechnology. Traditional silicon-based chips are reaching their physical limits, and the industry is increasingly looking towards materials like graphene, gallium nitride (GaN), and silicon carbide (SiC). These materials offer better efficiency, higher speed, and greater heat resistance, making them ideal for the next generation of chips, especially in high-power applications like electric vehicles and 5G infrastructure.

2. Extreme Ultraviolet Lithography (EUV)

Extreme Ultraviolet Lithography (EUV) is set to take center stage in 2024. EUV technology, which uses extremely short wavelengths of light to create smaller, more complex circuits, is crucial for the production of 5-nanometer (nm) chips and beyond. Leading chip manufacturers are investing heavily in EUV to push the boundaries of Moore's Law, aiming to create more powerful, energy-efficient chips.

3. Increased Focus on Sustainability

Sustainability is becoming a critical factor in chip manufacturing. As the environmental impact of the tech industry comes under greater scrutiny, companies are looking for ways to reduce their carbon footprint. This includes optimizing manufacturing processes, reducing waste, and recycling materials. Moreover, the demand for energy-efficient chips is rising, not just for environmental reasons but also to power the growing number of battery-operated devices and electric vehicles.

4. AI and Automation in Manufacturing

Artificial intelligence (AI) and automation are revolutionizing chip manufacturing. AI algorithms are being used to optimize production processes, predict maintenance needs, and improve yield rates. Automation, on the other hand, is enhancing precision and efficiency, particularly in the assembly and testing phases. These technologies not only improve the quality and consistency of chips but also help in scaling up production to meet the growing global demand.

5. Geopolitical Factors and Supply Chain Resilience

The global chip shortage experienced in the past few years has highlighted the importance of supply chain resilience. In 2024, we expect to see a continued emphasis on diversifying supply chains and reducing dependency on single sources. Geopolitical factors, particularly tensions between major tech powerhouses like the US and China, are prompting countries to invest in domestic chip manufacturing capabilities to ensure national security and economic stability.

6. The Rise of Custom Chips and RISC-V Architecture

There's a growing trend towards custom chip solutions, driven by companies like Apple and Google, who are designing their own chips to optimize performance and efficiency for their specific needs. Additionally, the open-source RISC-V architecture is gaining popularity, offering a customizable and cost-effective alternative to traditional chip architectures. This democratization of chip design could lead to more innovation and competition in the market.

7. The Challenge of Skilled Workforce Shortage

One of the major challenges facing the chip manufacturing industry in 2024 is the shortage of skilled workers. As the technology becomes more advanced, the need for highly trained engineers and technicians is growing. The industry is investing in education and training programs, but there's still a gap to be filled.

Conclusion

As we look at the year ahead, it's clear that the chip manufacturing industry is at a pivotal point. The convergence of new materials, advanced lithography techniques, sustainability concerns, geopolitical dynamics, and the increasing role of AI and automation are setting the stage for a transformative period. While challenges like skilled workforce shortages and supply chain complexities persist, the opportunities for innovation and growth are immense, promising a future where technology continues to evolve in exciting and unexpected ways.